Non-ferrous Metals

- Home

- Non-ferrous Metals

Non-ferrous metals

Non-ferrous metals tend to be more expensive than ferrous metals but are used for their desirable properties, including light weight (aluminium), high conductivity (copper), non magnetic properties or resistance to corrosion (zinc). Some non-ferrous materials are used in the iron and steel industries, such as bauxite, which is used for flux in blast furnaces. Other non-ferrous metals, including chromite, pyrolusite and wolframite, are used to make ferrous alloys. However, many non-ferrous metals have low melting points, making them less suitable for applications at high temperatures.

There are a large number of non-ferrous materials, covering every metal and alloy that does not contain iron. Non-ferrous metals include aluminium, copper, lead, nickel, tin, titanium and zinc, as well as copper alloys like brass and bronze. Other rare or precious non-ferrous metals include gold, silver and platinum, cobalt, mercury, tungsten, beryllium, bismuth, cerium, cadmium, niobium, indium, gallium, germanium, lithium, selenium, tantalum, tellurium, vanadium, and zirconium.

Non-ferrous metals are usually obtained from minerals like carbonates, silicates and sulphides before being refined through electrolysis.

The difference between ferrous and non-ferrous metals is that ferrous metals contain iron. Ferrous metals, such as cast irons or carbon steel, have a high carbon content, which generally makes them vulnerable to rust when exposed to moisture. However, this is not the case for wrought iron, which resists rust due to its purity, and stainless steel, which is protected from corrosion by the presence of chromium.

Mixed Heavy Metals

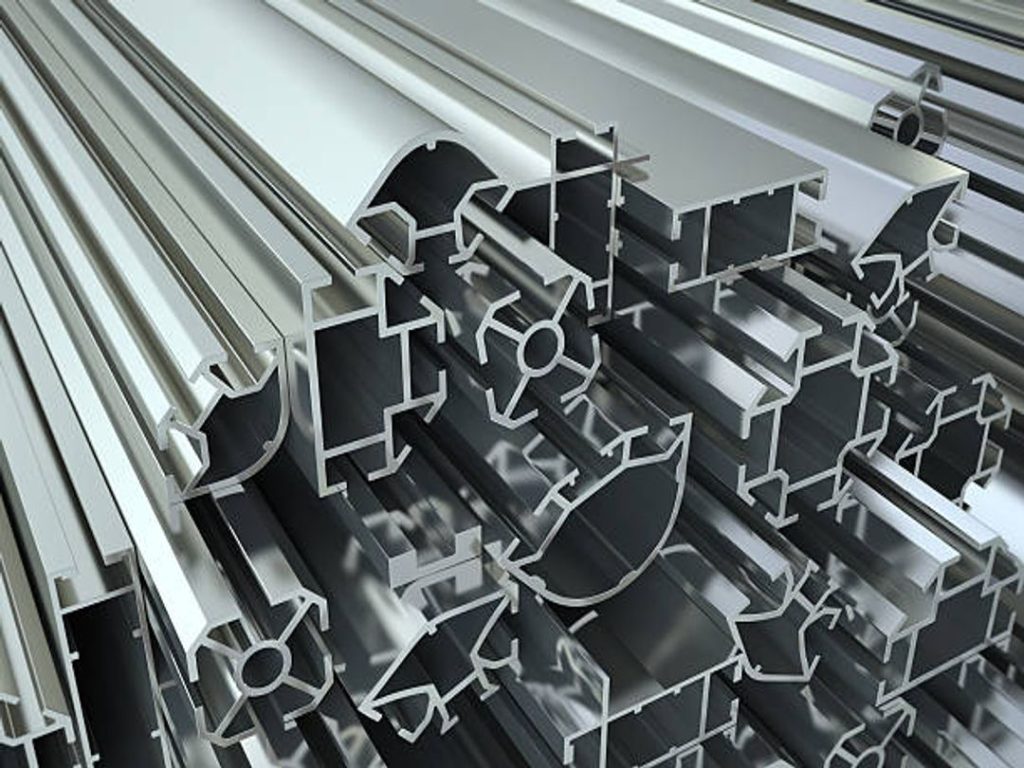

Aluminium Profiles

Mixed Aluminium Zorba

Shredded Fridge Aluminium

Wheel Balance Weight

Brass Pales/Pallu

Aluminium Pucks

Brass Hair Wires

Aluminium Wires

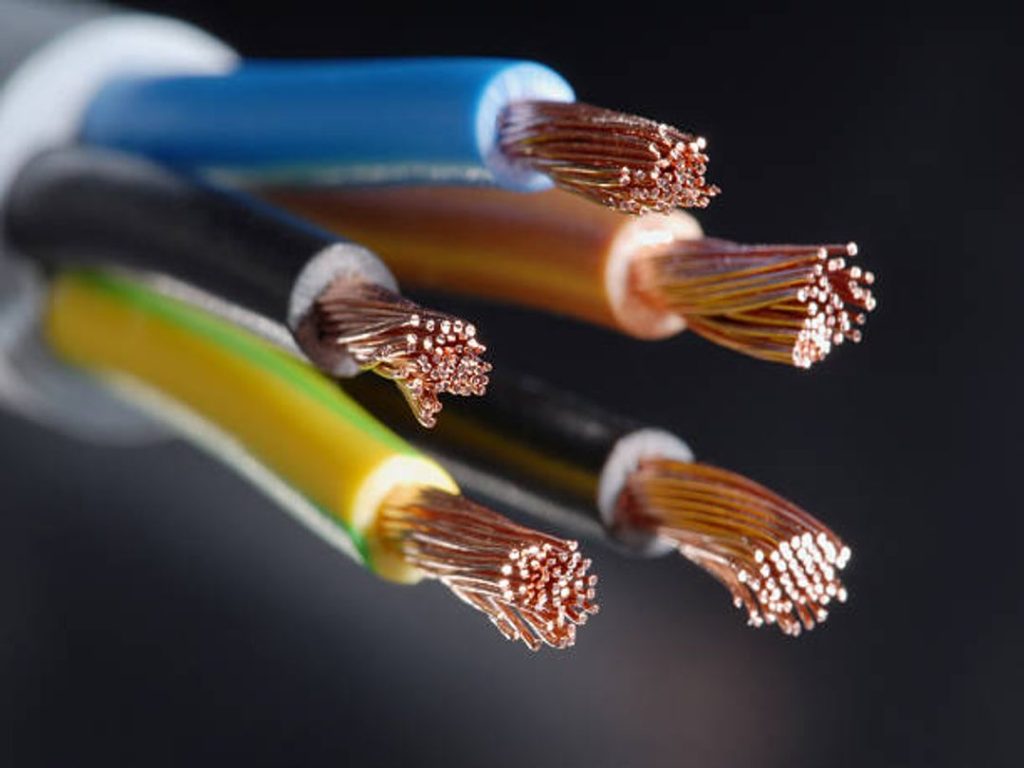

Copper Cables

Lead

Fridge Compressors

Copper Millberry

E-Meters

Car Starters

Copper Turnings

Stators and Rotors

Aluminium Wheels

Mixed Aluminium Body Motors

Zinc Sheets